Downtime poses a significant challenge for manufacturing organizations, often representing more than just a temporary setback in production. At its core, downtime translates into lost productivity, revenue, and potential reputation damage. In the intricate dance of manufacturing operations, any interruption can disrupt the finely tuned processes, leading to cascading effects throughout the supply chain.

Whether it’s a breakdown in machinery, unexpected maintenance issues, or even human error, the ramifications of downtime reverberate beyond the factory floor. In today’s hyper-competitive global market, where efficiency is paramount, every minute of halted production can translate into missed deadlines, lost contracts, and dissatisfied customers.

Moreover, downtime often comes with hidden costs, such as overtime pay for employees working to catch up on lost production, rush shipping fees for delayed orders, and the expenses associated with repairing or replacing equipment.

As manufacturing becomes increasingly automated and interconnected through technologies like the Internet of Things (IoT) and Industry 4.0 initiatives, the potential sources of downtime also multiply, underscoring the urgency for proactive strategies to mitigate its impact.

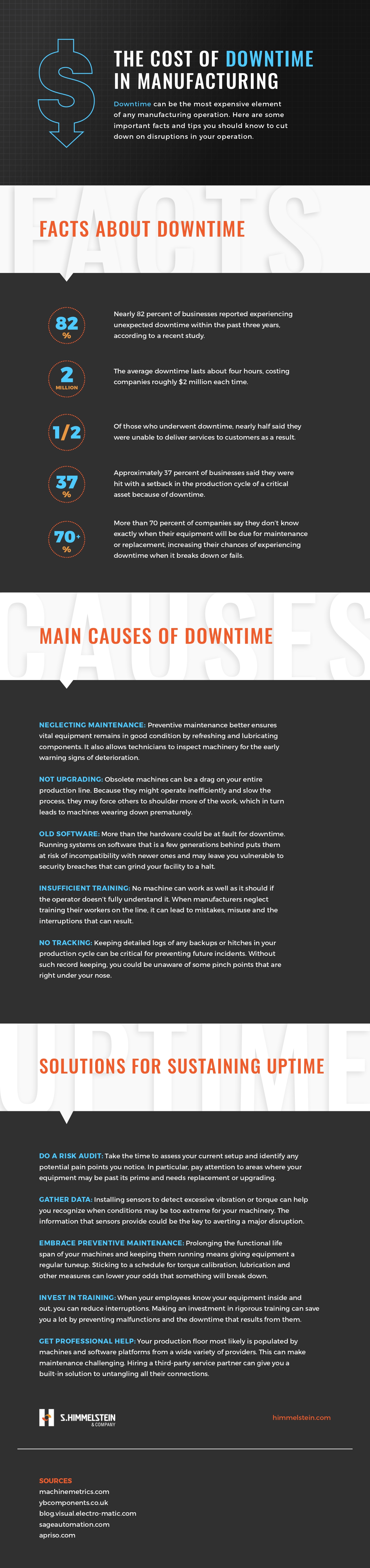

To learn more about the strategies being utilized to sustain uptime in these operations, check out the resource paired alongside this post.

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer